Raw material parts

Features of Precision Hot Forging by NISSIN PREVO

Able to provide small parts weighing 15g with high precision

NISSIN PREVO specializes primarily in small forged parts. Over the years, we have been manufacturing automotive parts that require high precision, and we have accumulated our own customization know-how for forging machinery to meet these requirements. We have enhanced our ability to manage dimensions and have established a system that can respond with ± 0.3mm precision.

Quality appears in aesthetics of products

We have also been thoroughly pursuing appearance quality. Technologies that pursue "beautiful surface" have resulted in accuracy of dimension precision. In addition, we are continuing to thoroughly reduce the defect rate through a total number of inspections (visual inspection of all products).

Planning and facility maintenance to ensure stable delivery

We do not have any delays in delivery of mass-produced products, such as more than 50,000 pieces of one product, and we are highly evaluated for stable delivery. There are two main points for ensuring delivery. One is to procure materials in a planned manner, which may take more than three months, ahead of schedule. The second is to conduct daily and monthly inspections to avoid delays caused by equipment trouble.

Forged parts

-

Construction machinery parts

Size/60×60×70 Material /SS400 -

Mission parts

Size/φ107×83 Material /SCr20 -

Automotive parts

Size/105×105×31 Material /SS400 -

Railway parts

Size/113×40×48 Material /SS400 -

Mission parts

Size/125×30×11 Material /SCr420H -

Shift fork

Size/80×55×35 Material /SCM415H -

Motorcycle parts

Size/70×60×30 Material /SCr420HZ -

Fitting

Size/45×30×17 Material /SUS316L -

Automotive parts

Size/85×30×50 Material /SCM435

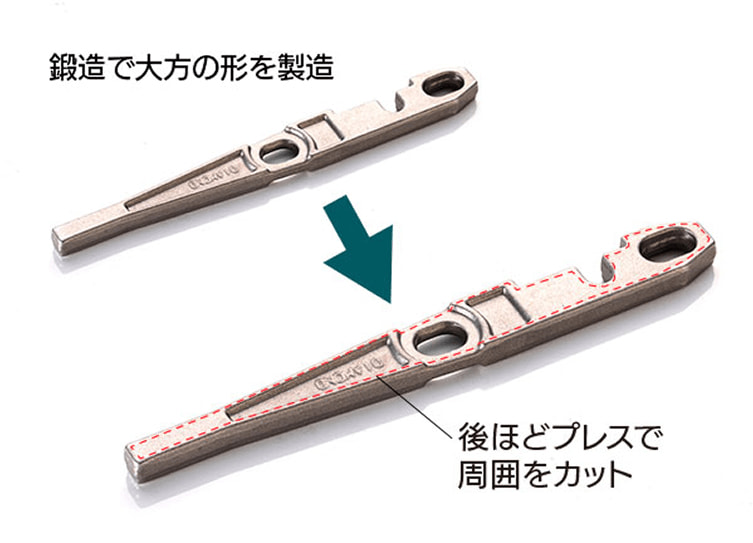

To companies engaged in punching press processing

Our hot forging to your punching press processing

What is a bottleneck in the punching of plate materials is the poor yield of materials. If a forging process is added as a front-end process and a large shape is manufactured, it will lead to a reduction in materials and processing time. As a result, it is cheaper in total than in the normal process, and the yield rate can be greatly improved compared to punching from the plate material. In this way, NISSIN PREVO is also receiving requests for pre-processing in forging.