Original parts

Hydrogen compliance to container and accessory inspections based on the High Pressure Gas Safety Law

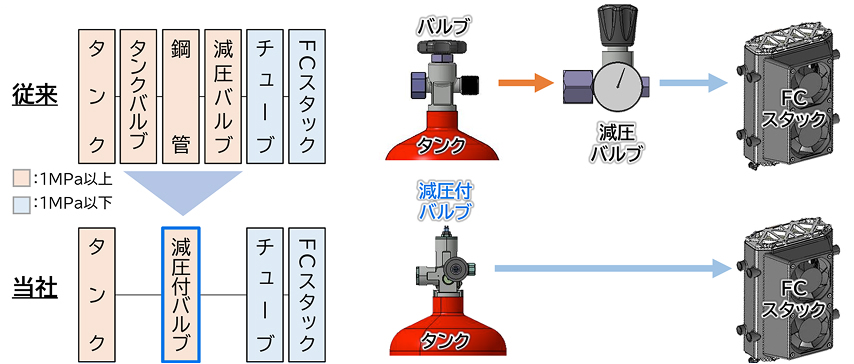

■Simplified system with pressure reduction mechanism

■Domestically usable, compliance with KHK

■Specifications can be customized

■Domestic lightest-class 310g

Tank valves with pressure-reducing mechanism are compatible with hydrogen. It's largest input-pressure is 35MPa, output-pressure is 0.05~0.09MPa. It's weight 310g is as lightest as in Japan. It reduced weight by simplification of the system and conforms to the High Pressure Gas Safety Law. Flow rate switching, pressure gauge, safety valve, etc. are selectable as basic specifications and options. Trial production and sales have begun ahead of the launch.

Advantage of our valve system over conventional valve systems

System simplification

Conventional valve systems require several components like tank-tank-valve-steel pipe-pressure reducing valve-tube-FC stack. The valve system of NISSIN PREVO has a simple structure of tank-valves with pressure reducing-tube-FC stack. Integration of the pressure reducing mechanism into the valve eliminates the need to install a separate pressure reducing valve, and reduces the number of pipes and parts.

Realization of weight reduction

The simplified configuration of the entire system reduces weight and contributes to the reduction of vehicle and equipment weight. The valves themselves are also designed to be domestic lightest-class 310g, particularly suitable for mobility applications with hydrogen systems.

Hydrogen compatibility and legal compliance

It conforms to the Container Accessories Inspection based on the High Pressure Gas Safety Law, and the product design meets the safety standards.

This product conforms to KHK (The High Pressure Gas Safety Institute of Japan) and can be used domestically.

Customizable specifications

Output pressure can be selected when ordering within 0.05~0.09MPa.

Flow rate (20~50 L/min) can also be specified, and optimum setting can be made according to the application.

Flow rate switching function, pressure gauge and pressure relief valve can be added as options. It can meet a wide range of needs.

Basic Specifications

| Item | Specifications |

|---|---|

| Gas used | Hydrogen |

| Body material | A6061-T6 or T651 |

| Input pressure | 3~35 MPa |

| Pneumatic test pressure | 58.4 MPa |

| Output pressure | 0.05~0.09MPa 1 |

| Flow rate | 20~50 L/min 2 |

| Exit | Rc1/8 |

| Gas used | Hydrogen |

| Tank line | 7/8-14 UNF |

| Hydrogen filling port | W22山14-LH |

| Operating temperature | -10~70 ℃ |

| Fusible plug | Operating temperature 75 to 90 °C |

| On-off valve | Manual |

| Weight | 310g |

- 1 Regarding the output pressure, please specify the pressure within the above range when order.

- 2 Regarding the flow rate, please specify the flow rate within the above range when order.

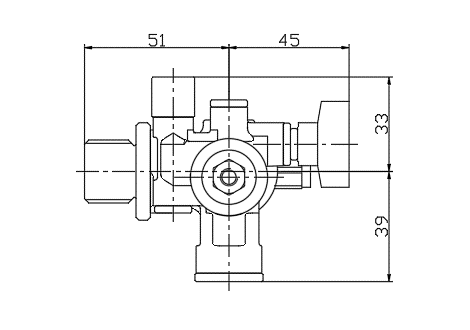

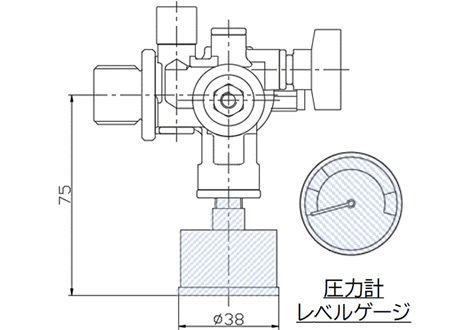

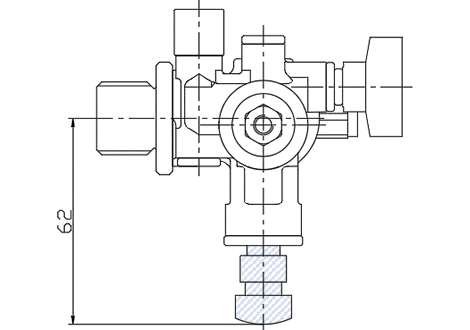

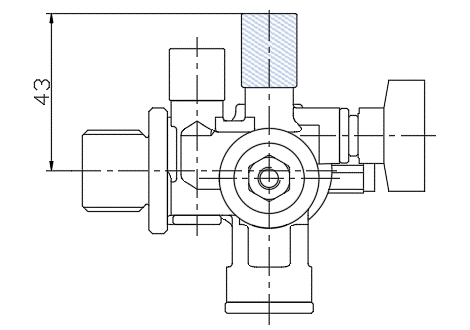

External dimensions

Option

| Item | Specifications | Weight |

|---|---|---|

| ① Flow rate switching | Lo/Hi two-step switching 3 | Approximate 35g |

| ② Pressure gauge A | Bourdon Tube 4 | Approximate 50g |

| ③ Pressure gauge B | Pressure sensor | Approximate 30g |

| ④ Pressure relief valve | Spring-loaded safety valve | Approximate 30g |

- 3 If you select flow rate switching as an option, specify a flow rate of 2 patterns within the flow rate range of the basic specifications.

- 4 The specifications might be changed.

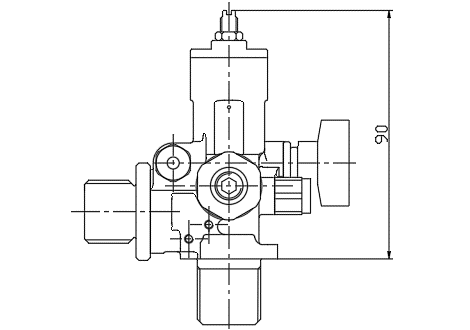

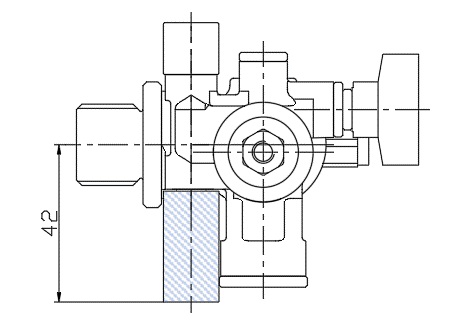

External dimensions

Output-voltage 0.5~4.5V Current consumption 3mA

Release-pressure 0.2MPa

(The setting value can be changed, please contact us.)