Technical Information

NISSIN PREVO provides not only tangible aspects such as various manufacturing parts, machines and tools, but also intangible know-how such as customer-friendly designing methods, proprietary software for machine control, prototype processing, and a complete quality-control system.

-

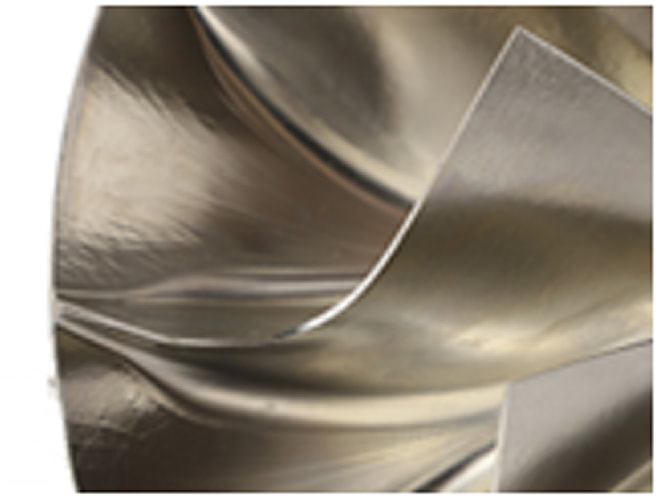

Technology of Materials processing

We produce high-quality parts and products in a variety of industries by making full use of advanced metal processing technologies such as casting, forging, rolling, extrusion, and drawing. These manufacturing methods make full use of the metal's properties. They are suitable processing technologies for products that require durability, strength, and precision.

-

Technology of Mass-produced parts

All manufacturing processes from hot forging, cold forging, and die casting to machining, heat treatment, and assembly are handled in an integrated manner. This enables us to strictly control the quality of products, and share information and make adjustments between processes. Thereby we can shorten delivery times and improve cost efficiency.

-

Technology of Prototype processing

We produce jigs, inspection tools, and cutting tools in-house to realize high-precision prototypes. Also, through close collaboration with affiliated companies and cooperating companies, we are able to respond in an integrated manner from the prototype stage to mass production, thereby realizing product delivery in a short time.

-

Technology of Quality assurance

As a Tier1 supplier, we constantly maintain high-quality standards and provide peace of mind based on the quality assurance system that we have built up over many years. This quality assurance system is thoroughly run in all manufacturing processes in order to comply with the strict quality standards required in the industry.