Technology of Mass-produced parts

Since in 1946, we have focused on the integrated processing from raw materials to machining, heat treatment, and finishing, and have been producing precision parts. Our manufacturing techniques and Tier1 quality-assurance systems, which we have accumulated since our founding, have been highly regarded and trusted.

Compatible with integrated processing and production

STEP 01~STEP 05's engineering processes include cold and hot forging, aluminum die casting, machining, heat treatment, and assembly. We propose optimal specifications from both raw material and machining aspects.

Integrated production also reduces transportation and management costs to heat treatment companies and machinery processors.

STEP01:Materials processing

Forging technology

We use a die forging method to form materials for products that require precision and strength.

Hot forging is mainly for automotive parts up to palm size.

Cold forging is for small precision parts that are attached to the tips of industrial sewing machines.

*Hot Forging Facility Size ⇒ 1,000~1,600t

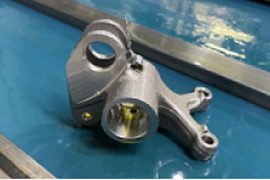

Materials processing (Aluminum die-casting)

Our die casting process is produced by a combination of reduced pressure mainly to improve the flow of melted aluminum and reduce the entrainment cavities, and local pressure to suppress the generation of shrinkage cavities.

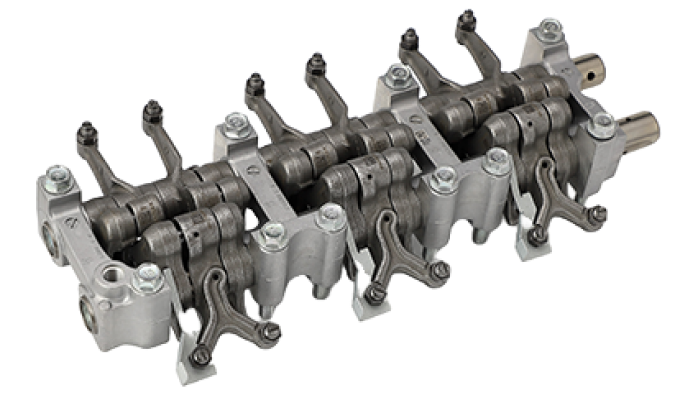

Our aluminum business is based on functional parts for automobile engines, which are used in extremely harsh environments.

STEP02:Machining

Our greatest strength is the processing of deformed small parts. Since its founding, we have been working to improve the efficiency of its general-purpose lines by building a specialized line for high-volume products through know-how accumulated over a half-century of experience and proactive improvement activities to maximize the use of existing facilities.

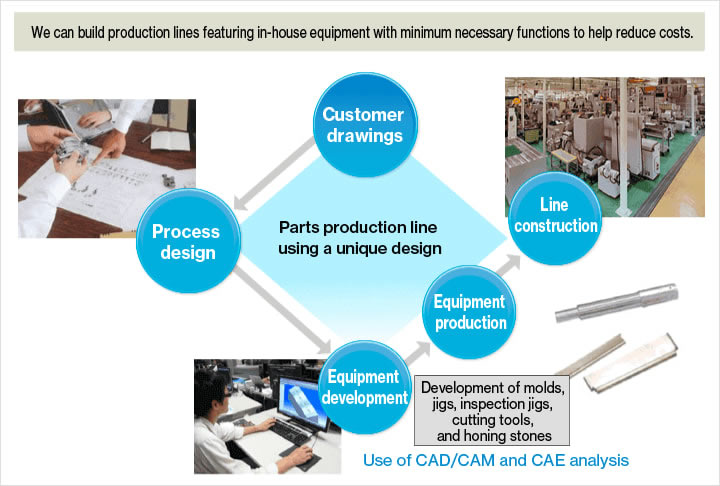

In-house production of equipment jig molds

By in-house production of processing equipment, dies and jigs,

we will propose the optimal processing method.

Building the line with in-house production facilities focused on minimal necessary functions,

we are pursuing cost reductions.

STEP03:heat and surface treatment

Heat treatment is an important process that determines the nature of metals.

NISSIN PREVO manufactures the heat treatment process in-house. Safe and high-quality heat treatment is performed with automated equipment.

Carburizing and carbonitriding can be processed in batch units, and subzero processing, vacuum hardening, copper brazing, etc. are possible. Surface treatment (subcontracted plant) also supports hard and strong DLC treatment, hard chrome plating, and copper-plating to prevent carburizing.

STEP04:Finishing machining, assembly and completion

Ultra-precision hole finishing using a honing machine manufactured by NISSIN ProSOL CO., LTD. is a technology that achieves particularly excellent precision and finish even in hole finishing where high-precision machining is required for precision parts and mechanical parts. In this processing method, the inner surface of the hole is finely polished using a honing machine to maximize dimensional precision and surface quality.