Aluminum Die Casting

High-strength die casting that is less internally defective due to pressure reduction and local pressures

Our die casting process is produced by a combination of reduced pressure mainly to improve the flow of melted aluminum and reduce the entrainment cavities, and local pressure to suppress the generation of shrinkage cavities.

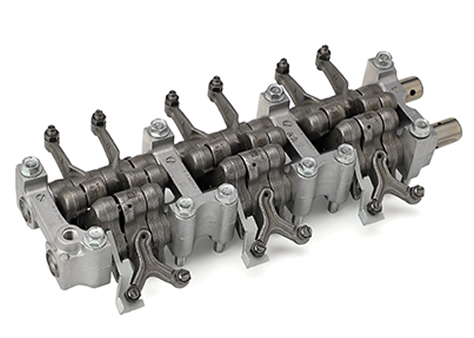

Our aluminum business is based on functional parts for automobile engines, which are used in extremely harsh environments.

Advantages of Aluminum Die Casting

- High-precision molding: Even complex shapes can be formed with high precision, and the finish is good, so it reduces the time for post-processing.

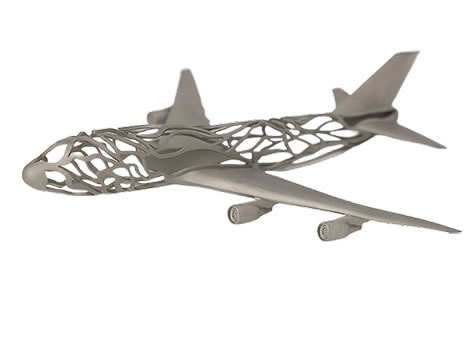

- Lightweight: Aluminum is lightweight, making it possible to reduce the weight of products. This is expected to improve fuel efficiency and durability, especially in the automobile and aircraft industries.

- High strength: Casting metal at high pressure allows the manufacture of high strength products.

- Adapted to mass production: High-speed mass production is possible, and a large number of parts can be manufactured in a short period of time with one mold.

- Excellent thermal conductivity: Aluminum has high thermal conductivity and is suitable for products that require cooling or heat treatment.

- Corrosion resilience: Aluminum itself is naturally anti-corrupt, and it has strengths in use, particularly in outdoor and harsh environments.

Specifications for aluminum die casting

The features and specifications of our aluminum die casting are as follows.

●Features

- Zero casting defects

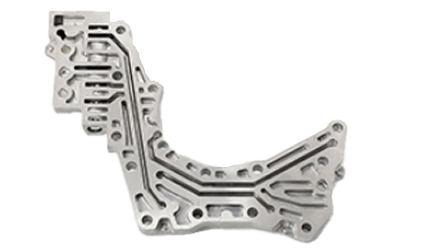

- Optimal Shape Proposal Utilizing the Strengths of Integrated Processing/li>

- Realization of high strength by reduced pressure and local secondary pressures

- "Artificial aging hardening treatment" is possible by adoption of the secondary pressurization system

- Through the use of the reduced pressure method, casting defects are reduced, that contributes to the strength UP. (Max. Decomposition:-95kpa)

The features and specifications of our aluminum die casting are as follows.

●Equipment owned

- Number of tons: 350

- Die size: 650×650mm/ projected area 520cm2

- Bases: 7

- Number of tons: 800

- Die size: 1,100×1,100mm/ projected area 1,188cm2

- Base: 1 unit