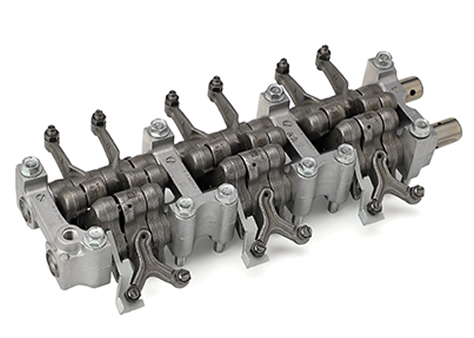

Iron Forging

"Forging" to increase strength by striking iron

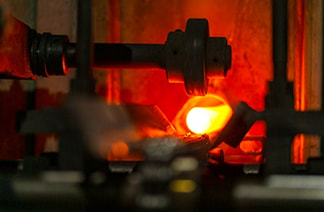

Forging is a technology for forming metal (iron) heated to 1200 degrees by applying pressure using an upper die and a lower die. Forging has the property that metal structure can be strengthened while changing shape by applying force to metal. That is the word "Strike while the iron is hot" itself. Forging is to change the metal shape while strengthening by heating them to a high temperature.

Advantages of Iron Forging

- Metal flow along the shape (fiber flow) is formed, increasing strength.

- Complex shapes can be formed because the metal is heated until it softens.

- Secondary processing (machining) can be reduced because a shape close to the final shape can be molded

- Internal organization becomes dense due to large pressure, and internal defects are eliminated.

- Materials can be reduced compared to cutting out.

- Mold life is long because softened metal is on, and mass production is possible in a short time.

- Less variation in dimensions

Iron Forging Specifications

Precision hot forging of Iron

Our forgings are manufactured by hot forging method. We have a technology and production system that increases precision as much as possible. Hot forging is a forging method that handles large material amount change. It provides the highest hardness by generating fiber flow.

●Features

- Thermal Management and Scale Removal for Beautifully Finishing Product Skin

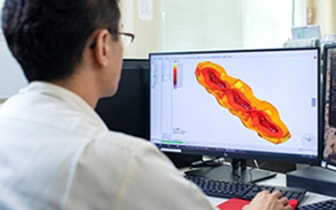

- Select the most appropriate equipment and construction method with the power of information analysis

- Mold design and polishing process for proper fiber flow

●Specifications

- Compatible materials: SS, SC, SCM, SCr

- Size: Material diameter: φ14 to φ50 Material length: 65~285mm

- Lead time: 15 to 30 days (minimum) after order receipt

- Tolerance :±0.3 mm

- Production capacity :

L Hammer 1.3t...2 base 200,000 shots/month L manual crank press 630t~1,600t 250,000 shots/month