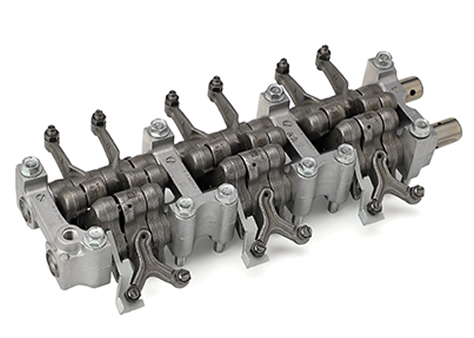

Stainless Steel Forging

Stainless Steel Forging requiring large load

Stainless steel is harder than the iron used in general forging and requires a greater load than iron. Also, controlling temperature of stainless steel is difficult and it requires severe temperature management. Furthermore, mold wear tends to be severe, so it is necessary to regularly manage molds to ensure quality. Since we manufacture metal molds in-house, we are able to respond precisely to everything from design to use and maintenance.

Advantages of Stainless Steel Forging

- Since it is more expensive than iron, there is a large merit of forging closely to a finished form. It leads to a reduction in materials.

- Because stainless steel is more difficult to machine than iron, the total cost can be reduced by forging.

- Stainless steel is often used in fluid-related applications because it is difficult to rust as its name suggests. From the use intention point of view, it is compatible with forging that does not have internal defects, such as leaks.

Equipment for Stainless Steel Forging

Precision Hot Forging of Stainless Steel

Our forgings are manufactured by hot forging method. We have established a technology and production system that pursues precision. Hot forging is a forging method that handles large material amount change. It provides the highest hardness by generating fiber flow.

●Features

- Thermal Management and Scale Removal for Beautifully Finishing Product Skin

- Select the most appropriate equipment and method with the power of information analysis

- Mold design and polishing process for proper fiber flow

●Specifications

- Compatible materials: SUS303, SUS304, SUS316, SUS410

- Size: Material diameter: Material diameter: φ14 to φ50 Material size: 65~285mm

- Lead time: 15 to 30 days (minimum) after order receipt

- Tolerance :±0.3㎜

- Production capacity :

L Hammer 1.3t...2 units 200,000 shots/month

L Manual crank press 630t~1,600t 250,000 shots/month