Prototype Processing Technologies

We manufactures jigs, inspection tools, and cutting tools in-house. We have a prototype order system among Group and partner companies. Through them, we can provide the integrated processing from cutting to heat treatment, grinding, and assembly assurance, as well as meeting short delivery times. Please leave it to NISSIN PREVO from the development stage.

Compatible with all prototype processing.

We provide metal parts prototypes with high-precision, high-quality processing. We can respond to a wide range of needs from various kinds of prototypes to mass-produced products by making full use of precision processing technologies. We support customer's ideal product development by our highest quality and precision.

-

Difficult-to-process and deformed material processing

Compatible with difficult-to-cut materials such as Inconel 718 and Inconel 713C, MAR-M-247.

Applying our technologies and know-how accumulated as Tier1 for many years through numerous machining to the latest cutting-edge facilities. Cutting with high precision and high efficiency. -

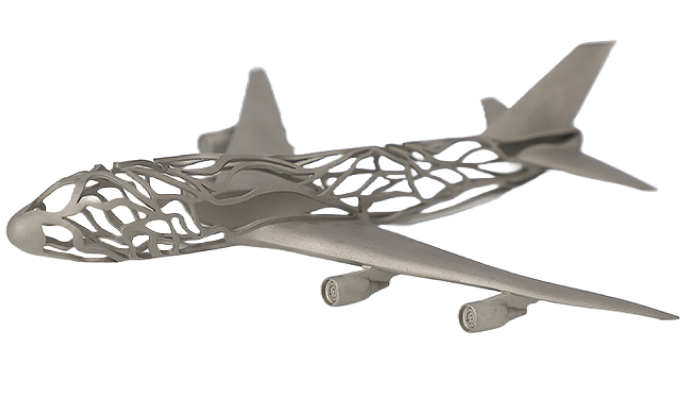

Metal 3D printers

Own M290 of EOS, made in Germany. By using a laser-based powder lamination molding method in a medium-sized machine, it is possible to carry out not only material prototyping but also processing to the final product.

-

Equipment Introduction

Equipped with state-of-the-art facilities such as CNC lathes including Harmley's C42 and C32, high-rigidity and high-performance, and GF's HSM600U LP with automation WorkPartner, high-speed and high-performance, as well as machining centers, and EDM machines.

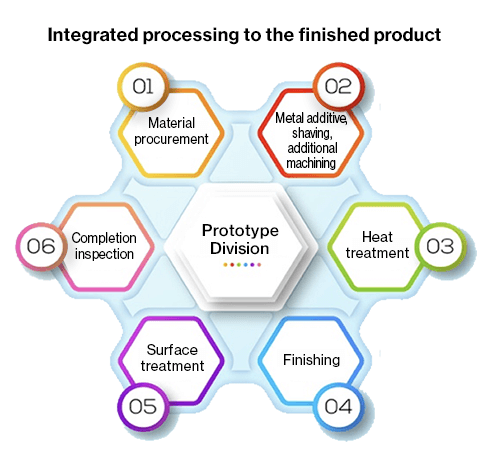

Prototype division (Prototype section)

~Integrated processing to finished products

- Point01:

Integrated processing from in-house material procurement to finishing - Point02:

We are confident in processing difficult-to-cut materials. - Point03:

We are confident in ultra-precision hole finishing.