List of Equipment

NISSIN PREVO introduces equipment that supports advanced technologies.

We are actively installing the latest equipment to achieve higher-precision and highly accurate processing.

- List of Equipment

- MACHINING

- MULTI-AXIS LATHE MACHINING

- CNC LATHE

- WIRE-CUT EDM

- 3D METAL PRINTER

- CAD/CAM

- GRINDING

- RINDING

- HONING

- ELECTRIC FURMACE

- LASER MARKER

- MEASUREMENTS

- OTHERS

| Equipment classification | Plant | Manufacturer | Model |

|---|---|---|---|

| MACHINING | Chitose Plant | HERMLE | 5-axis vertical machining center C42U |

| HERMLE | 5-axis vertical machining center C32U | ||

| GF Mikron | 5-axis vertical machining center HSM600U LP | ||

| YASDA | 5-axis vertical machining center YBM-950 Ver.III | ||

| Sodick | 5-axis vertical machining center HS650L | ||

| YASDA | 5-axis vertical machining center YBM-850 | ||

| YASDA | 4-axis vertical machining center YBM-950 | ||

| KITAMURA | 3-axis vertical machining center MYCENTER3XiF | ||

| TSUGAMI | 3-axis vertical machining center VNT4-III | ||

| brother | Compact machining center SPEEDIO S700 x1N, S500 xd1 | ||

| Suge Plant | Yasuda Kogyo | Horizontal machining center < H40i-24PLS > | |

| Sodick Corp. | Vertical machining center < HS650L > | ||

| Yasuda Kogyo | Vertical machining center (CNC Jigborer) < YBM950V ・ YBM950V Ver3 > |

||

| MORI SEIKI | Vertical machining center <NV6000> | ||

| MORI SEIKI | Vertical machining center < NV4000 > | ||

| MORI SEIKI | Horizontal machining center < NHX4000 > | ||

| OKK | Vertical machining center <VM53R> | ||

| OKK | Vertical machining center <VM4III・VM4II> | ||

| OKK | Vertical machining center <VM43R> | ||

| MULTI-AXIS LATHE MACHINING | Chitose Plant | MORI | Multi-Processing Machine NTX2000 |

| CNC LATHE | Chitose Plant | OKUMA | CNC lathe LB15II-M |

| TAKISAWA | CNC lathe TC-2MII | ||

| Suge Plant | Okuma Corporation | Multi-Processing Machine (Macton) | |

| MORI SEIKI | NC lathe <NLX2500SY/700> | ||

| MORI SEIKI | NC lathe <CL1500> | ||

| MORI SEIKI | NC lathe <NL1500SY> | ||

| Okuma Corporation | Vertical CNC lathe < V100R > | ||

| MORI SEIKI | NC lathe <SL204> | ||

| WIRE-CUT EDM | Chitose Plant | Sodick | Electric Discharge Wiring Machine AP650L |

| brother | Electric Discharge Wiring Machine HS-70A #1 | ||

| brother | Electric Discharge Wiring Machine HS-70A #2 | ||

| Suge Plant | Sodick Corp. | Die sinking EDM <AQ35L> | |

| Sodick Corp. | Die sinking EDM <AG40L> | ||

| Sodick Corp. | Wire Electric Discharging machine<AP250L> | ||

| Sodick Corp. | Wire Electric Discharging machine<AP450L> | ||

| Sodick Corp. | Wire Electric Discharging machine<AP500L> | ||

| Sodick Corp. | Wire Electric Discharging machine<AP650L> | ||

| Sodick Corp. | Wire Electric Discharging machine<SL400Q> | ||

| Makino milling cutter | Wire Electric Discharging machine<UP53i・EU64> | ||

| 3D METAL PRINTER | Chitose Plant | NTT DATA | EOS M 290 #1 |

| CAD/CAM | Chitose Plant | CAD/CAM system | NX-Siemens PLM Software |

| CAD/CAM system | TOP/Solid TOP/Cam v6 | ||

| CAD/CAM system | EUKLID Solutions for CAD/CAM | ||

| NC machining simulation software | VERICUT | ||

| NC machining simulation software | G-Navi | ||

| CAD/CAM systemム | Master cam | ||

| GRINDING | Chitose Plant | OKAMOTO | Flat Grinder PGS 63 EN |

| NAGASEI | High precision contouring SHSD-80 | ||

| TOYO | Vertical grinder TVG-35C-2S | ||

| SHIGIYA | Universal grinding machine GSU-30 B/75 P | ||

| Western Automatic Equipment | Cylindrical super finishing machine CN-350NC | ||

| RINDING | Suge Plant | Nagashima Seiko | Surface grinder (NC precision grinder) <WAZA730-NC> |

| Okamoto Machine Tool | Flat surface grinders<PSG84 EN・PSG63 SA> | ||

| Nagashima Seiko | Cylindrical Grinder (NC Ultra Precision Multi-purpose Cylindrical Grinder) <NMGL-2HW> |

||

| TOYODA KOKI | Cylindrical Grinder <GOP 32×50・GOP 32×100> | ||

| Okamoto Machine Tool | Rotary surface grinder <PRG6DX> | ||

| HONING | Chitose Plant | NISSIN | Honing machine E25-MM2N |

| NISSIN | Honing machine CMH-E50-N-D | ||

| NISSIN | Honing machine SMH-100-N2H | ||

| ELECTRIC FURMACE | Suge Plant | Fulltec Corp. | Part Annealing Furnace <FTM-1300G-600> |

| LASER MARKER | Suge Plant | Brother Industries Ltd. | Fiber Laser Marker <LM-3200F> |

| MEASUREMENTS | Chitose Plant/Suge Plant | ZEISS | Three-dimensional measuring machine PRISMO ultra |

| JENOPTIK | Shaft Measuring Machine OPTICLINE C614 | ||

| ATOS | 3D scanning Core200 | ||

| FARO | 3D scanning Edge 6ft | ||

| Mitutoyo | Contour measuring instrument FORMTRACER SV-C4500 | ||

| Tokyo Seimitsu | Surface roughness meter SURFCOM1400D-12 #1 | ||

| Tokyo Seimitsu | Roundness meter RONDCOM54DX | ||

| Shimadzu Corporation | Precision universal testing machine AG-100KNISMO | ||

| Keyence Corp. | 3D Scanner-Type Three-Dimensional Measuring Instrument VL-730 | ||

| Keyence Corp. | 3D Imaging Dimension Measuring Instrument LM-X100T | ||

| Shimadzu Corporation | Microfocus X-ray CT System inspexio SMX-225CT FPD HR | ||

| Keyence Corp. | Digital Microscope VHX6000 | ||

| Keyence Corp. | Laser Elemental Analytical Microscope VHX-800_EA300 | ||

| Antonpaar | NanoIndentation Testing Machine NHT3 | ||

| Antonpaar | RST300 of lever test scratch testing machine | ||

| Antonpaar | Carotester CAT2 | ||

| OTHERS | Chitose Plant | TOHO KOKI | Centrifugal barreling machine TAB-304H |

| TIPTON | Centrifugal barreling machine HS-R801B |

HERMLE 5-axis Machine Machining Center C42U

■Features

- Rigidity, temperature change, vibration/resonance-resistant structure due to adoption of artificial stone frame

■Compatible work size

- Outer diameter: Maxφ800 × H560mm

- Maximum payload: 1,400 kg

- Applicable to difficult-to-machine materials: Ni-based heat-resistant alloys, etc.

HERMLE 5-axis Machine Machining Center C32U

■Features

- Rigidity, temperature change, vibration/resonance-resistant structure due to adoption of artificial stone frame

■Compatible work size

- Outer diameter: Maxφ800 × H560mm

- Maximum payload: 1,400 kg

Applicable to difficult-to-machine materials: Ni-based heat-resistant alloys, etc.

+ GF+Mikron 5 axis machine

Machining center HSM 600 U LP

■Features

- Polymer concrete base suppresses head flexibility and absorbs vibration well.

- High-speed machining is possible with high rigidity and the best balance during machining.

- Automatic work changer enables continuous unmanned operation for a long period of time.

■Compatible work size

- Outer diameter: Maxφ800 × H560mm

- Maximum payload: 1,400 kg

DMG MORI Multi-Processing Machine

NTX2000/ with bar feeder

■Features

- 2-spindle 1 turret + B-axis

■Compatible work size

- Wide range of applications, including deformed objects, shafts, composite objects, plate objects, and gears

- Bar material φ54 x 1,000mm allows continuous unmanned machining

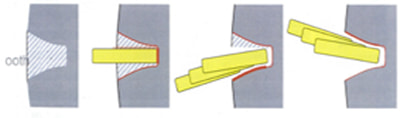

- InvoMilling processing available

InvoMilling machining is to complete gear grooving with a typical tool by means of a multi-function machine or a 5-axis machine.

This is a comprehensive solution that combines tools, machinery, and the machining program that connects them.

EOS M290 LASER

(400W×1)

■Features

- Using metal materials, it forms prototypes, final products, and molds directly from 3D data.

- Dimensions (mm)

250×250×325 - Compatible materials

AlSi 10 Mg(ADC 3)・INC 718・ Maraging steels - Option

Parameter Editor

Heat plating system (Max200°C)